Published on Apr 02, 2024

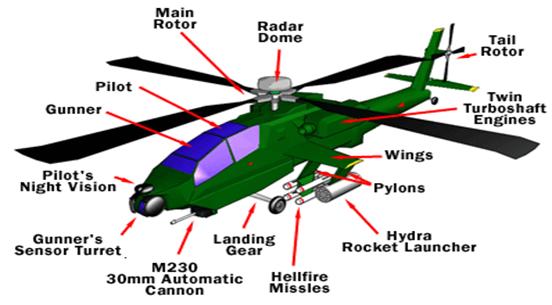

The Apache Helicopter is a revolutionary development in the history of war. It is essentially a flying tank- a helicopter designed to survive heavy attack and inflict massive damage. It can zero in on specific targets, day or night, even in terrible weather. As you might expect, it is a terrifying machine to ground forces.

In this topic, we look at the Apache's amazing flight systems, engines, weapon systems, sensor systems and armour systems. Individually these components are remarkable pieces of technology. Combined together they make up an unbelievable fighting machine - the most lethal helicopter ever created.

The first series of Apaches, developed by Hughes Helicopters in the 1970s, went into active service in 1985. The U.S military is gradually replacing this original design, known as the AH-64A Apache, with the more advanced AH-64D Apache Longbow. In 1984, Mc Donnell Douglas purchased Hughes Helicopters, and in 1997, Boeing manufactures Apache helicopters, and the UK-based GKN Westland helicopters manufacturers the English versions of the Apache, the WAH-64.

DRAG: Drag is an aerodynamic force that resists the motion of an object moving through a fluid. The amount of drag depends on a few factors, such as the size of the object, the speed of the car and the density of the air.

THRUST: Thrust is an aerodynamic force that must be created by an airplane in order to overcome the drag. Airplanes create thrust using propellers, jet engines or rockets.

WEIGHT: This is the force acting downwards or the gravitational force.

LIFT: Lift is the aerodynamic force that holds an airplane in the air, and is probably the important of the four aerodynamic forces. Lift is created by the wings of the airplane.

Lift is a force on a wing immersed in a moving fluid, and it acts perpendicular to the flow of the fluid but drag is the same thing, but acts parallel to the direction of the fluid flow.

1. Air approaching the top surface of the wing is compressed into the air above it as it moves upward. Then, as the top surface curves downward and away from the air stream, a low pressure area is developed and the air above is pulled downward toward the back of the wing.

2. Air approaching the bottom surface of the wing is slowed, compressed and redirected in a downward path. As the air nears the rear of the wing, its sped and pressure gradually match that of the air coming over the top. The overall pressure effects encountered on the bottom of the wing are generally less pronounced than those on the top of the wing.

The following relationships must be true:

THRUST = DRAG

WEIGHT = LIFT

If for any reason, the amount of drag becomes larger then the amount of thrust, the plane will slow down. If the thrust is increased so that it is greater than drag, the plane will speed up.

If the amount of lift drops below the weight of the airplane, the plane will descend. By increasing the lift, the pilot can make the airplane climb

Apache works in the same way as any other helicopter. It has two rotors that spin several blades. A blade is a tilted airfoil, just like an air plane wing. As it speeds up through the air, each blade generates the lift

The main rotor, attached to the top of the helicopter, spins six meter blades. As the main rotor spins, it exerts a rotation force on the entire helicopter. The tail rotor blades work against this force-they push the tail boom in the opposite direction. An Apache has double tail rotors, each with two blades.

The pilot maneuvers the helicopter by adjusting a swash plate mechanism. The swash plate changes each blade’s pitch to increase lift. Adjusting the pitch equally for all blades lifts the helicopter straight up and down. Changing the pitch as the blades make their way around to the rotation cycle creates uneven lift, causing the helicopter to tilt and fly in a particular direction.

Fig: The rotor assembly on an AH -64A Apache

The swash plate mechanism has two primary roles:

Under the direction of the collective control, the swash plate can change the angle of both blades simultaneously. Doing this increases or decreases the lift that the main rotor supplies to the vehicle, allowing the helicopter to gain or lose altitude.

Under the direction of the cyclic control, the swash plate can change the angle of both blades individually as they revolve. This allows the helicopter to move in any direction around a 360 o circle, including forward, backward, and left and right.

The core structure of each blade consists of five stainless steel arms, called spars, which are surrounded by a fiberglass skeleton. The trailing edge of each blade is covered with a sturdy graphite composite material, while the leading edge is made of titanium. The titanium is strong enough to withstand brushes with trees and other minor obstacles, which is helpful in "nap-of-the-earth" flying (zipping along just above the contours of the ground). Apaches need to fly this way to sneak up on targets and to avoid attack. The rear tail wing helps stabilize the helicopter during nap-of-the-earth flight as well as during hovering

The Apache Helicopters use turbo shaft jet engines to power their rotors. Some older or smaller helicopters use "reciprocating" (Piston) engines for their power source, but most of the helicopters in use today use gas-turbine engines. They are light, very powerful and economical. The best part is that they are very reliable as well. Failure rates for gas-turbine engines are very low because there are not as many internal moving parts as there are in a reciprocating engine.

A jet engine works on four very simple principles: "Suck, Squeeze, Burn and Blow". The picture posted here shows a simple gas-turbine engine cross section. In the front of the engine is the compressor section which "Sucks" in air and "Squeezes" it to make it denser and better for combustion. Air is brought into the compressor by the turning compressor blades that are shaped like little airfoils. It works like a big fan to move air into the engine. In between the moving rows of compressor blades are stationary blade sets called "stators". The stators change the direction of the airflow and help in the compression process.

The area that the air can occupy gets smaller as the air travels through the compressor. The air then goes through the diffuser section which transports the air neatly into the combustion chambers, which are in the combustion section. There the air is mixed with fuel and is ignited to create a powerful reaction. (The "Burn" part) The explosive burned fuel and air mixture then travels into the turbine section where the force is turned into a combination of drive power and thrust (or exhaust). If the force is converted mainly into drive power to drive a transmission, as in most helicopters, then it is referred to as a turbo shaft engine. If the force is only converted to enough power to drive the compressor, and the rest is used as thrust, then it is considered to be a turbojet (or thrust producing) engine.

The newest Apache sports twin General Electric T700-GE-701C turbo shaft engines, boasting about 1,700 horsepower each. The power is transferred from the engine using a main gearbox which changes the power from the engine and sends it to the transmission. In the transmission RPM is reduced from thousands of RPM to hundreds of RPM. By doing this the torque is increased and the rotation is slowed to an acceptable level for the rotor system. The transmission drives the mast which gives direct rotation to the rotors. Often another shaft will come out of the transmission to directly drive the tail rotor as well.

An accessory gearbox mounted on the engine draws little engine power to drive things like the oil pump, the generator and the fuel control for the engine itself.

| Are you interested in this topic.Then mail to us immediately to get the full report.

email :- contactv2@gmail.com |